YANTRA takes pleasure in developing diamond processing technology that is based on artificial intelligence (AI) and building relationships based on trust. It has pushed the boundaries over time to create some amazing products that will enable you to fulfill your aspirations. It not only designs new items to fit your diamond processing facility, but it also updates existing ones to stay up to date.

While having developed a wide range of diamond processing machinery in the past, YANTRA has come up with the product “OPTIMUS 2.0” a diamond processing machine that can do all the processes individually with the latest revolutionary 'Next-Gen Technology with Automatic Pressure Management', which is introduced for the first time in the world.

our vision

- Revolutionize industries through intensified technological creativity and automation.

- Enhance productivity, efficiency, and sustainability in a rapidly evolving world.

- Ideal pathway for circular economy with enhanced efficiency.

- We envision a future industry that involves revolutionary solutions driven by passion, innovation, and excellence.

our mission

- Prioritize our client benefit and satisfaction.

- Proficient in designing, manufacturing, and supplying diamond industry products.

- Business growth across diverse markets and geographies.

- Diverse and committed individuals with integrity, focused on mission fulfillment.

value statements

- Our primary focus at Yantra Innovations is to consistently prioritize the satisfaction and benefit of our clients.

- As a prominent entity, we possess proficiency in the complete spectrum of designing, manufacturing, and delivering products specifically tailored for the diamond industry.

- Automation emerges in optimizing the circular economy, amplifying overall efficiency.

1998

Lathe

LATHE was the first bruting machine manufactured by Yantra Innovation.

It was a single spindle bruting machine and the girdle was executed by rubbing a diamond on to another diamond.

2004

Mexi

The very second machine manufactured by Yantra Innovations was the MEXI Machine.

In this machine, Girdle was produced using PCD (Polycrystalline Diamond).

2006

Rainbow

The RAINBOW was the first machine to use a ceramic wheel.

It was a Russian Bruter in which Girdle was executed by a ceramic wheel.

The RAINBOW was executing diamonds of above 30 cents.

2008

Nano

The miniature version of RAINBOW was NANO.

It was also the Russian Bruter but for small sizes.

In the NANO machine the Girdle was produced by a ceramic wheel.

The NANO was executing diamonds which were less than 50 cents.

2009

Arrow

ARROW was established with a ceramic wheel which could perform pavilion conning.

It was the very first pavilion conning machine with a ceramic wheel in the diamond industry.

2010

Pre-Angle

The PRE-ANGLE is also called a 2 in 1 machine because it was able to execute both the ceramic wheel girdle and pavilion conning.

It was the only machine which was executing more than 1 task.

2011

Witforce

The WITFORCE was a Crown Coning machine.

It was also designed with the ceramic wheel after 4P.

It contained unique Claw Holding technology.

It is the first machine which was able to perform crown conning.

2012

Witter

The WITTER was the upgraded version of WITFORCE.

It was added to Crown Conning After 4P, as the word ‘WIT’ is used to describe the crown conning in the diamond industry.

2013

Rayno

RAYNO was the advanced girdle bruting machine for diamonds from 1 cent to 1 carat.

2014

Rayno – Gol

RAYNO-GOL had the unique oscillatory girdle bruting technology

The machine was specifically made for tiny diamonds

It had the capability to process diamond sizes less than 10 cents.

2015

iBLOCK

The iBLOCK was designed as a Table Blocking machine.

The iBLOCK was the 1st machine to have two sensors to measure the frictional pressure between diamond and the ceramic wheel.

2016

All in One

AIO is the first machine to incorporate crown and pavilion faceting with a ceramic wheel.

The machine is called the 4 in 1 because it can perform four tasks.

Girdle + Pavilion Conning + Crown Conning + Table Blocking.

The ALL IN ONE has a unique up-down movement.

2017

Pre – Blocking

The Introduction of cup wheel technology for diamond blocking was introduced through this machine.

The machine contains Unique up-down movement.

It is the first machine with artificial intelligence to measure and adjust pressure to suit high tension stones.

2018

AIO+

AIO+ was the first machine in which Dual Wheel Technology was introduced.

It contained combinations of all the processes

Girdle + Pavilion Conning + Crown Conning + Table + Crown and Pavilion Faceting.

2019

Sarva

The SARVA is the machine to have “Wheel wear auto compensation” for improved accuracy.

It Introduced direct transfer of Sarin plan files for processing.

SARVA executes Top 16 and Bottom 16 Faceting along with Girdle and Table.

2020

Dhruva

DHRUVA is the most accurate fixing station specifically developed for the forthcoming OPTIMUS.

It has the facility to transfer directly without removing the diamond from Pavilion to Crown or Crown to Pavilion.

It is also compatible for both light and heat curing.

2021

Optimus 1.2

Optimus 1.2 is equipped with numerous advanced features and dual-wheel technology.

It is the ultimate one-stop solution for all your needs before the final polishing of precious diamonds.

2024

Optimus 2.0

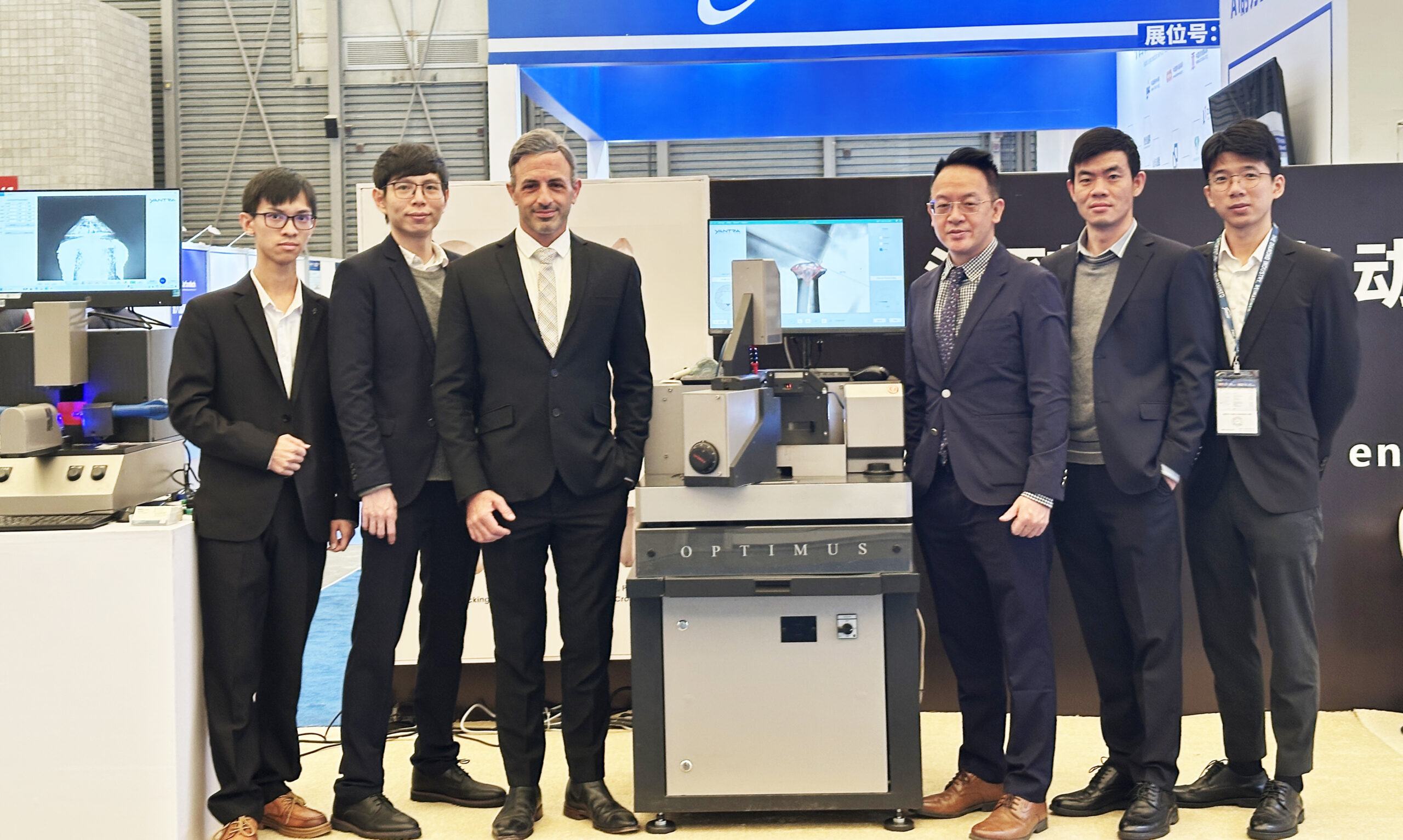

Introducing our latest product, the 'OPTIMUS 2.0'

Optimus 2.0 is packed with Next-Gen Technology, featuring Automatic Pressure Management, automatic facet skipping, auto calibration, series blocking process, and much more.

For more details, visit our product page or review the brochure.